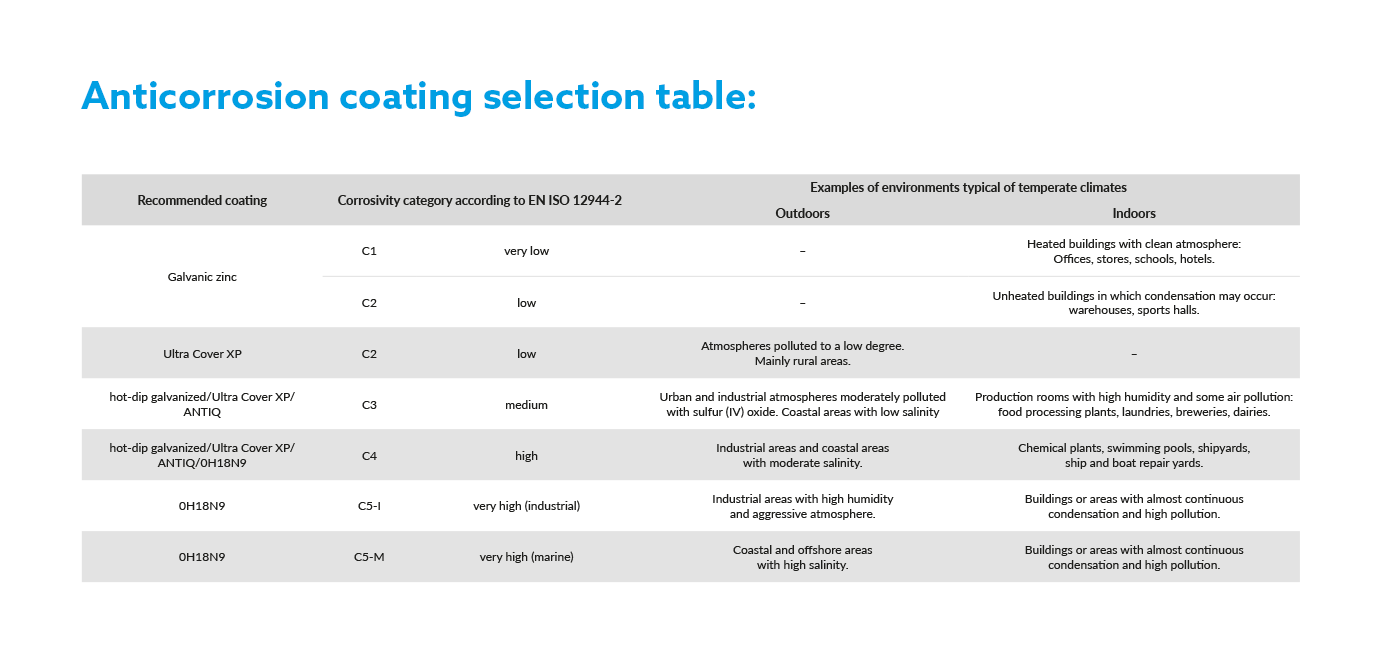

Our latest development is the Ultra Cover XP anti-corrosion coating group, which protects products, leaving behind previous technologies of galvanizing and hot-dip galvanizing. Ultra Cover XP consists of coatings of the lamellar type and thick-film passivation - thanks to this it has a very high resistance to external factors. The lamellar galvanizing is perfect for fasteners - screws, nuts, rods. Resistance to corrosion is up to 1000 hours in a salt chamber and at the moment it is the highest resistance available on the market.

Ultra Cover XP is:

• Excellent corrosion resistance

• No chromium presence

• High resistance to temperature and chemical agents

• No occurrence of hydrogen embrittlement in the material

Galvanic zinc

This is the most common way to protect the metal surface. Metal elements protected with galvanizing are intended for indoor installation.

Hot-dip galvanized

The thickness of the zinc coating ranges from 45 to 150 microns. Hot dip galvanizing is an exceptional protection against corrosion and the effects of atmospheric factors. Hot dip galvanized products are primarily intended for outdoors, where they are in contact with atmospheric factors.

Stainless steel

The exceptional corrosion resistance of stainless steel is due to the process of the material passivation. The oxide layer formed, despite its very thin thickness, provides resistance to the penetration of corrosive media and determines the resistance to aggressive environments.