przyłącza

-

Produkty

Katalog PDF

- Nowości produktowe

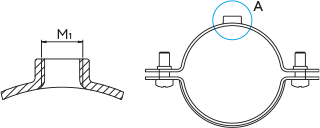

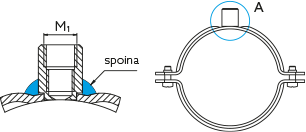

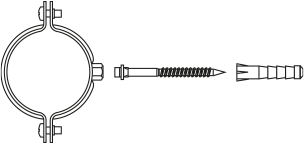

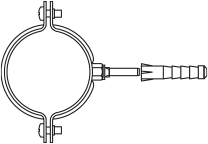

- Obejmy z okładziną

- Obejmy bez okładziny

- Punkty stałe i podpory ślizgowe

- Wibroizolatory

- System zawiesi linkowych

- Obejmy i akcesoria do wentylacji

- System podpór dachowych i podestów serwisowych

- Zestawy wsporcze

- System instalacji przeciwpożarowej

- Bierne zabezpieczenia przeciwpożarowe

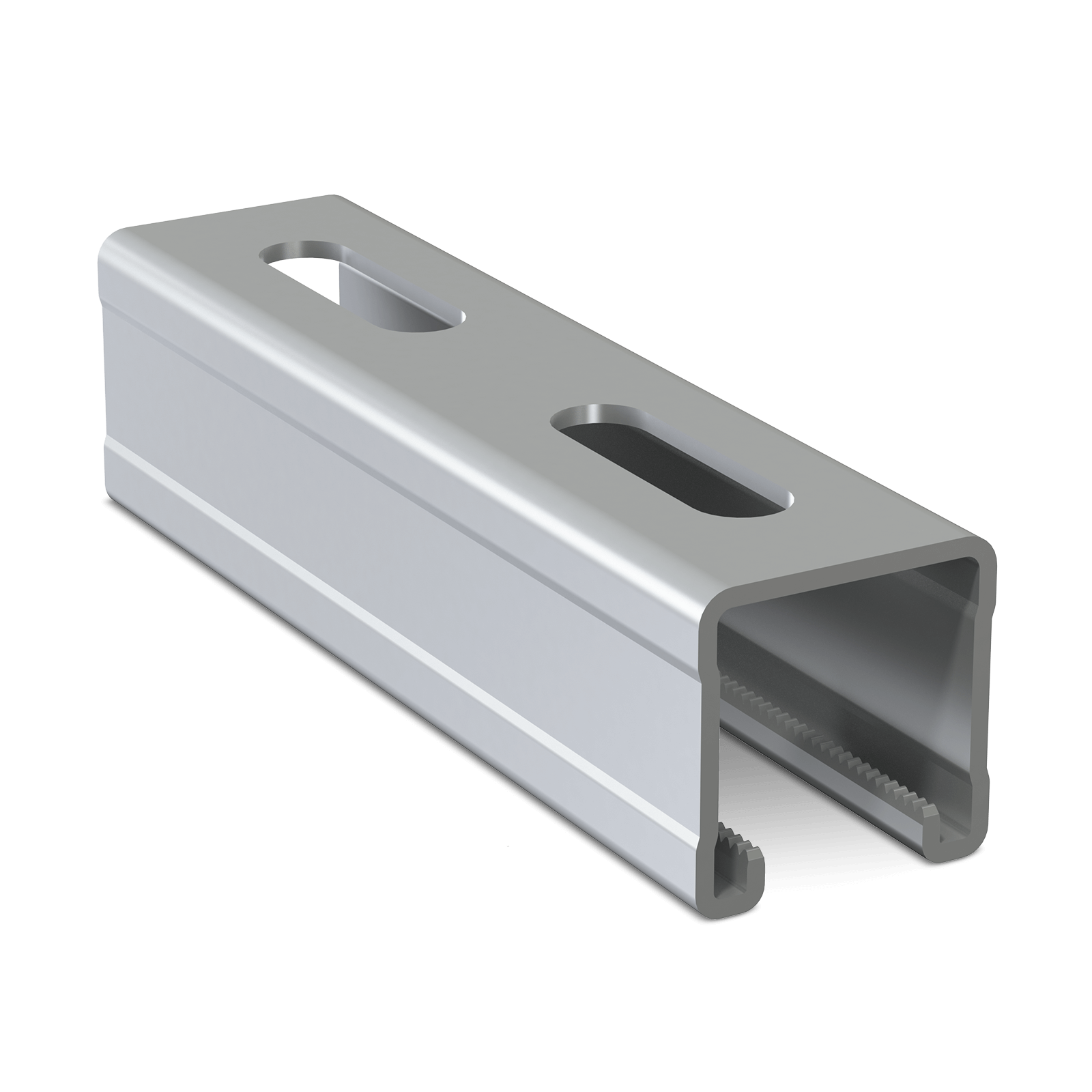

- System profili montażowych

- Akcesoria do systemu profili montażowych

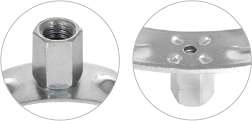

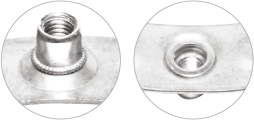

- Akcesoria montażowe i elementy złączne

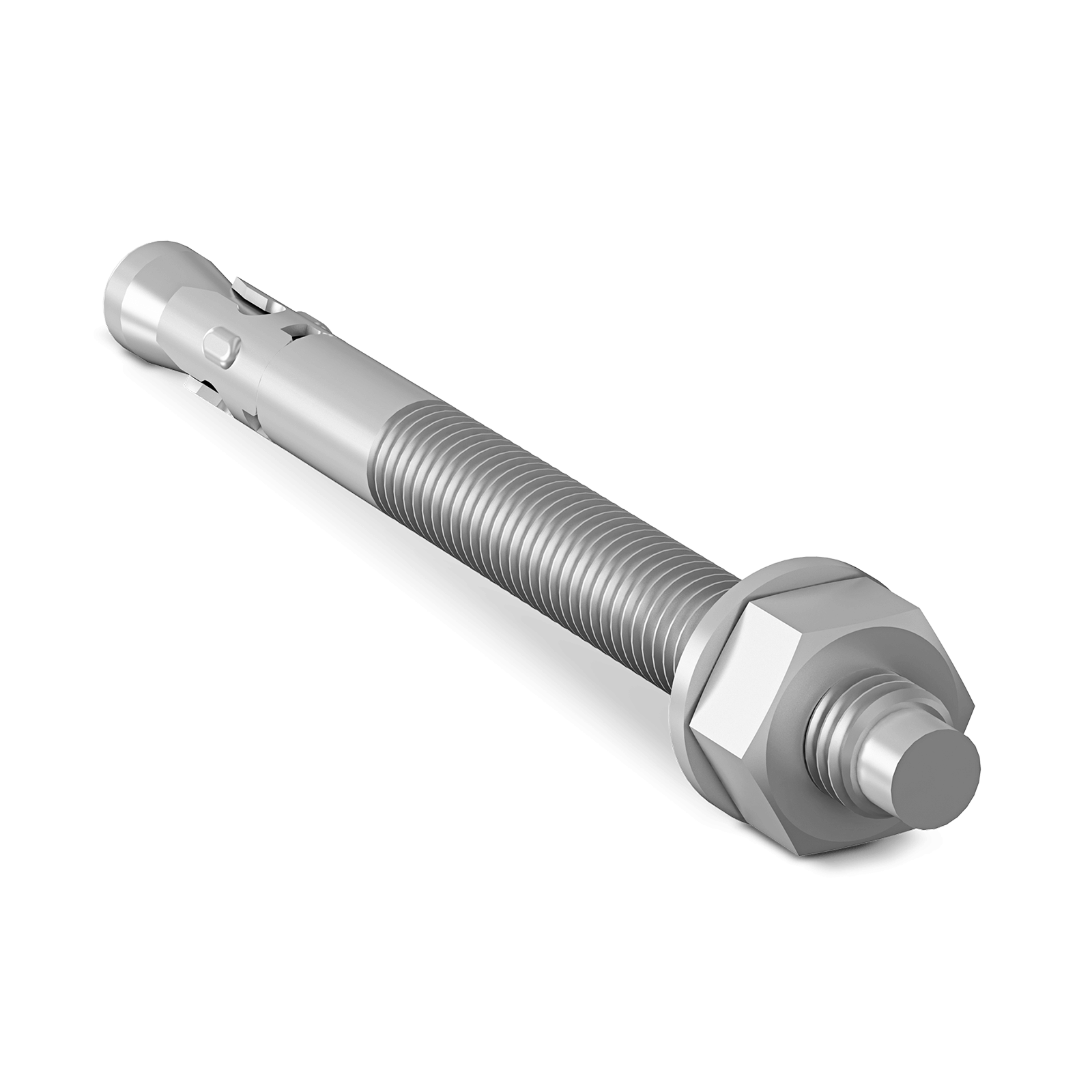

- Akcesoria kotwiące

- Ergonomia pracy instalatora

- Wyroby ze stali nierdzewnej (A2)

- Wyroby cynkowane ogniowo

- Wyroby w powłoce Ultra Cover XP

- System profili ciężkich CERTA

-

Strefa dystrybutora

PL

PRZENOŚNIKI

PL

-

Produkty

Katalog PDF

- Produkty

- Nowości produktowe

- Obejmy z okładziną

- Obejmy bez okładziny

- Punkty stałe i podpory ślizgowe

- Wibroizolatory

- System zawiesi linkowych

- Obejmy i akcesoria do wentylacji

- System podpór dachowych i podestów serwisowych

- Zestawy wsporcze

- System instalacji przeciwpożarowej

- Bierne zabezpieczenia przeciwpożarowe

- System profili montażowych

- Akcesoria do systemu profili montażowych

- Akcesoria montażowe i elementy złączne

- Akcesoria kotwiące

- Ergonomia pracy instalatora

- Wyroby ze stali nierdzewnej (A2)

- Wyroby cynkowane ogniowo

- Wyroby w powłoce Ultra Cover XP

- System profili ciężkich CERTA

-

Strefa dystrybutora

włącz dźwięk powiadomienia czatu